cement plant equipment layout

BASIC CEMENT PLANT LAYOUT - gwmcn

2020year4month7day 1. Limestone Quarry and Crushing Plant. The major raw material for cement production is limestone. The limestone most suitable for cement production must have

[خذ المزيد]

(PDF) Handbook for Desinging Cement Plants - Academia

Cement plant operation handbook. jorge pinedo sanchez. Download Free PDF View PDF. Free PDF. Production of Cement. Engr Sajid Chaudhary. Download Free PDF View

[خذ المزيد]

PROCESS ENGINEERING FOR THE CEMENT LIME

2020year10month6day MAIN PROCESS EQUIPMENT BID DOCUMENT PREPARATION ... Cement plant as part of the plant upgrade project. Votorantim North America - St Mary´s

[خذ المزيد]

The Cement Plant Operations Handbook - International

2019year4month30day The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel

[خذ المزيد]

Plant Layout - An Accepted Challenge

2020year1month1day Plant layout encompasses layout for new green field cement plant and new installation as well as improvement in the layout of existing installations. Plant layout

[خذ المزيد]

(PDF) Optimizing Ready Mixed Concrete Production Plants

2014year11month3day Chemical Engineering Batch Conference Paper Optimizing Ready Mixed Concrete Production Plants via a Genetic Algorithm Approach Used for Batching Plant

[خذ المزيد]

Modernizing cement manufacturing in China leads to

2022year11month17day NSP rotary kilns started to account for more than 10% of the market share in 2001, and China’s national cement production peaked in 2014. Therefore, 2001

[خذ المزيد]

Experiences with the design of large size cement plants

2007year4month29day Three 8,000 tpd capacity cement plants have been ordered this year by one company to be erected at different geographical locations. The equipment will be

[خذ المزيد]

Cement plant performance optimization Benchmarking,

2021year2month16day Cement plant’s performance levels to maintain smooth system operation. Monitoring frequency and service modules are cus-tomizable so plants can match them to their own site requirements. Key Performance Indicators (KPIs) are accessed from a smart database (DataPRO), including confi-gurable events such as: triggers, time stamps,

[خذ المزيد]

(PDF) Optimizing Ready Mixed Concrete Production Plants

2014year11month3day Optimizing Ready Mixed Concrete Production Plants via a Genetic Algorithm Approach Used for Batching Plant Equipment Layout November 2014 DOI: 10.1061/9780784413777.059

[خذ المزيد]

The Cement Plant Operations Handbook - International

2019year4month30day Emergency power – 12. Plant control systems 6. Cement milling process summary data – 8. Typical equipment downtime 110 1. Storage of clinker and other components – 2. Cement milling – 3. Separators (classifiers) – 4. Ball mill circuit control – 5. Cement storage – 6. Cement dispatch – 7. Distribution – 8.

[خذ المزيد]

Experiences with the design of large size cement plants

2007year4month29day The topographical features of the site itself consist of several contours, hilly terrain and high altitude with a site elevation of 1370 amsl which may arguably make this plant the largest cement plant to be set-up at such a high altitude. Under normal conditions the utilized equipment is sized to produce 12,000 t of clinker per day.

[خذ المزيد]

How to design a cement processing plant? - LinkedIn

2023year2month17day cement processing plant. Designing a cement processing plant involves several steps, including determining the location, assessing the raw materials, selecting the equipment, and designing the ...

[خذ المزيد]

How to Start a Cement Factory

1. Clarify Your Production Scale and Cement Type. The first thing to do when you are planning to start a cement factory is to determine which type of cement you are going to produce and how many tons you are going to produce per day. The most widely used cement for concrete works is ordinary portland cement (OPC), apart from that, there is

[خذ المزيد]

BASIC CEMENT PLANT LAYOUT - gwmcn

2020year4month7day 1. Limestone Quarry and Crushing Plant. The major raw material for cement production is limestone. The limestone most suitable for cement production must have some ingredients in specified quantities i.e., calcium carbonates, silica, alumina, iron, etc. Typically, cement plant locations are based upon the availability of good quality limestone ...

[خذ المزيد]

Stacker And Reclaimer – Cement Plant Equipment Stacker

Stacker And Reclaimer. Stacking Capacity: 50-2000t/h. Circular Field Diameter: 50-150m. Application: limestone, coal, and other cement raw materials. SEND INQUIRY. The stacker and reclaimer is a kind of pre-homogenization equipment, mainly used for stacking and reclaiming bulk materials, such as limestone, coal, chemicals, etc.

[خذ المزيد]

How to Plan Design a Manufacturing Plant Layout? (Video Examples ...

2021year12month28day Since the equipment and building are already drawn on the computer, this step is more of a “drag and drop” process. On the computer, the designer will move around equipment, change its orientation, and find the best place for the physical pieces. Jump to 2:34-5:50 in the video below to see how it works in practice. 5.

[خذ المزيد]

Concrete Plant Standards - cpmb

2017year3month31day PART 3 — Plant Mixer Equipment Concrete Plant Standards of the Concrete Plant Manufacturers Bureau CPMB 100M-00 Twelfth Revision - Effective November 4, 2000. TABLE OF CONTENTS 1. Specifications for Equipment 1.1. Bins or Silos 1.1.1. Bins, Aggregate 1.1.2. Bins or Silos, Cement 1.1.3. Multiple Compartment

[خذ المزيد]

Concrete Batching Plants - MEKA Global

Concrete Batching Plants are used for manufacturing of high-quality in a variety of construction applications, like buildings, roads, bridges, airports and many others. MEKA offers a wide range of Ready Mix plants along

[خذ المزيد]

Ordinary Portland Cement Production AGICO

The Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding, cement packing, etc. In these processes, we need the

[خذ المزيد]

Gypsum Board Manufacturing Plant For Sale

STEP 1: Raw Material Preparing Spraying. Gypsum powder, water, and additives are fed into the mixer through the automatic metering system and conveying system to form gypsum slurry. The gypsum slurry is sprayed

[خذ المزيد]

(PDF) Mining Activities, Cement Production Process and

2022year7month4day Cement has hydraulic properties like slaked lime and hardens when mixed with water. Compressive strength increases in time and reaches its practical top limit after 28 days. Mixing crushed stone ...

[خذ المزيد]

Modernizing cement manufacturing in China leads to

2022year11month17day NSP rotary kilns started to account for more than 10% of the market share in 2001, and China’s national cement production peaked in 2014. Therefore, 2001 and 2014 are selected as typical years ...

[خذ المزيد]

CONCRETE BATCHING PLANTS - mekaglobal

2022year10month13day Complete Plants and Equipment to the Concrete Plants and Mineral Processing sectors. The name MEKA is synonymous with efficiency and quality in more than 110 countries around ... 12 2 units K 110 Stationary Concrete Plants Equipped With Fiber Dosing System, Hinkley Point-C Nuclear Plant Construction Project, UK 8 STATIONARY

[خذ المزيد]

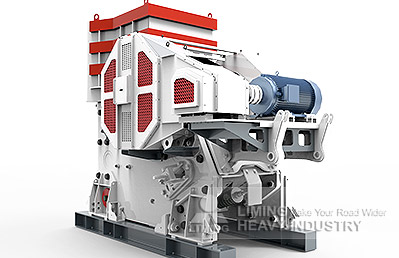

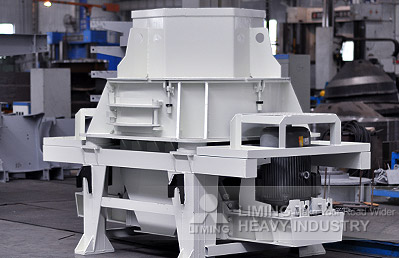

Stone Crushing Plant - Automatic Stone Crusher Plant AGICO

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment. The designed output is generally 30-350 tons per hour. According to different technological requirements, we can also equip the dust ...

[خذ المزيد]

PROCESS ENGINEERING FOR THE CEMENT LIME

2020year10month6day MAIN PROCESS EQUIPMENT BID DOCUMENT PREPARATION ... Cement plant as part of the plant upgrade project. Votorantim North America - St Mary´s Cement. ... Votorantim North America - St Mary´s Cement Water System – Plant Layout. info@saxuming saxum.us saxuming PROJECTS

[خذ المزيد]

(PDF) Techno-economic analysis of selecting the

PDF On Aug 1, 2016, M. Ghanbari and others published Techno-economic analysis of selecting the aggregate supply system based on optimal equipment layout in ready-mixed concrete plants Find ...

[خذ المزيد]

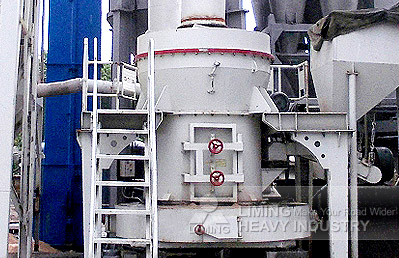

PLANT LAYOUT OF CEMENT INDUSTRY FOR MASS PRODUCTION-Full

2020year1month3day The optimum plant layout of cement industry proceeds quickest flow of material at the right quantity and quality of output at the lowest possible cost of manufacturing and with the least amount of handling in ... 26 3.2 Machinery or equipment in cement industry. Jetty. Hopper. Conveyor (belt, bucket etc). Silo (For clinker and

[خذ المزيد]- موقع فك وتركيب طواحين الاسمنت العمودية

- محطم المحمولة المصنوعة في تركيا

- بوصة الصخور المسحوقة

- طحن آلة الموردون في ناجبور

- ماليزيا طحن مطحنة الكرة الصانع

- كسارة المطرقة kapur

- البازلت الحجر الأزرق كسارة

- عملية تكسير الحجر في كسارة الحجر

- كسارة البنتونيت السودان

- الركام الناعم في تعدين الخرسانة

- indowana bara تعدين الفحم ، pt

- الاستثمار في تعدين الفحم

- مصنع كسارة الحجر في جوجرانوالا

- تفعيل البنتونيت تفعيل خط المعالجة

- سنگ شکن موتور دیزل

- معدات التعدين لدلو كسارة الذهب

- بابا الصين سهلة التركيب آلة كسارة الفك tuff

- المطاحن نهاية الكرة الصغيرة بأفضل الأسعار ونوعية جيدة دائما

- كسارة صخور الجرانيت الصغيرة

- التنقيب كسارات الصخور للبيع أستراليا

- الاسمنت معدات المصنع الرسوم المتحركة العمل

- نوار نقاله پیچ عامل اندونزی

- الشركة المصنعة لكسارة الهند

- الصابورة دراسة الجدوى

- المحمول مضغوط صغير الكسارات

- بيسلي المطرقة مطحنة الاسيان

- كيف تعمل الكسارة المخروطية الهيدروليكية كسارة الحجر

- تحقق النحاس خام تركيز مصنع مصنع

- كسارة متنقلة أولية في جنوب أفريقيا

- دليل تعليمات مطحنة المطرقة pdf

© Copyright - PETER&X محطم