rock crusher maintenance tools

Crushing and Screening Handbook - AusIMM

2021year6month24day quality rock materials for demanding construc-tion projects, such as bridges. Crusher automation – ensures consistent and effi cient operation. Improves

[خذ المزيد]

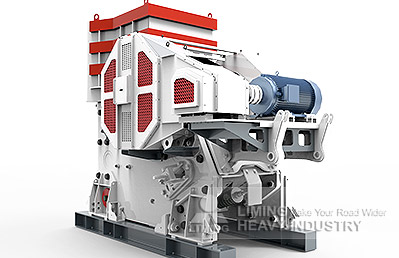

Understanding three different types of crusher

2018year3month15day These predictive maintenance tools can be used to help learn and understand the rock crusher’s normal operating condition or characteristics. Once the normal operating condition or characteristics

[خذ المزيد]

Tips for Crusher Maintenance - Thomasnet

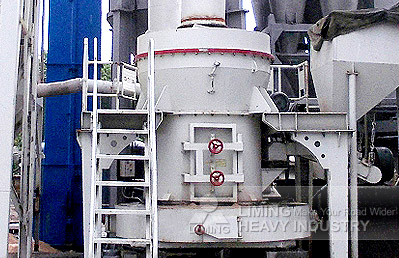

2018year11month28day Grinding Mill Commonly associated with the agricultural industry, grinding mills are a type of crusher that creates a compression

[خذ المزيد]

crusher maintenance

Implementing a preventive maintenance program is the best method of keeping a crusher in good operating condition for a long period. Preventive maintenance will include scheduled checks, inspections and services at

[خذ المزيد]

Reliability centered maintenance of cone crusher: a case study

2014year2month25day Cone crushers are extensively used for rock fragmentation and as a secondary crusher or tertiary crusher in a crushing circuit. The different parts of the cone

[خذ المزيد]

Reliability centered maintenance of cone crusher: a case

2017year8month24day The purpose of this paper is to focus the application of reliability centered maintenance with an aim to improve the reliability of the cone crusher. reliability tools

[خذ المزيد]

Crusher services - Metso

Metso provides a wide variety of preventive maintenance activities for crushers: Audit and inspection services Supervisory services Maintenance planning and kits Onsite

[خذ المزيد]

7 Tips for Rock Crusher Lubricant System

2022year10month28day Let’s change that. Here are seven tips toward maximizing the effectiveness of your rock crusher lube system. 1. Clean Rock Crusher Lubrication Systems Regularly. The first tip is simple: keep your lubricant

[خذ المزيد]

Rock Crushing Equipment Rock Crushers

Rock Crusher Types. Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business. We also custom-design top-performing crusher systems from the industry's best

[خذ المزيد]

SANDVIK CJ815 JAW CRUSHER - SRP

2023year9month14day Maintenance tool box Lifting tool for jaw plates Lifting tool for cheek plates JAW PLATE ALTERNATIVES CC, ST, HD CC, ST, HD Moving alternatives CC, ST, HD Alloys for jaw plates M1, M2, M8 Lifting tool for jaw plates Yes CRUSHER DRIVE SYSTEM MOTOR CHARACTERISTICS Manufacturer WEG Model W22 Type Three-phase,

[خذ المزيد]

A Detailed Overview of Cone Crushers and What

2020year6month3day Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

[خذ المزيد]

Lifting tools that promote safety first - Quarry

2013year5month2day The jaw liner lifting tool is used to lift the liner from the storage position (floor, pallet or other open container) to the crusher or from within the crusher during jaw liner change or reversal. Both lifting eyes are inserted into the elongated lifting holes and rotated 90 degrees in the recess cast into the fitting face of the jaw liner ...

[خذ المزيد]

Crushing it: A Comprehensive Guide to Stone Crusher Plants

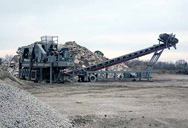

2023year2month28day Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in quarrying, mining, construction, and recycling operations. Stone crusher plants consist of several components, including a primary crusher,

[خذ المزيد]

Reliability centered maintenance of cone crusher: a case study

2014year2month25day A cone crusher is used for crushing rock. The vast majority of these installations are found in mineral processing plants. The Reliability of the crusher influences the productivity of the plant. The purpose of this paper is to focus the application of reliability centered maintenance with an aim to improve the reliability of the cone crusher. reliability

[خذ المزيد]

Mining Equipment: A-Z List for Maintenance Contractors

2022year2month15day A piece of excavating equipment consisting of a boom-mounted cutting head, a loading device – usually involving a conveyor, and a track to move the whole machine forward into the rock face. Rock Breaker. A machine to break large rocks into smaller pieces. Typically used to process oversize rocks that are too big for a crusher.

[خذ المزيد]

Metso Nordberg® C Series™ jaw parts

2018year10month15day 14 Maintenance tools Maintenance tools Using the appropriate lifting tool for a specific wear part is crucial. When installing jaws, the Metso jaw crusher maintenance platform and the specially designed lifting tool can be used. These tools, designed exclusively for Metso jaws, improve working conditions by making it

[خذ المزيد]

Rock Crusher Maintenance Crusher Mills, Cone Crusher, Jaw

rock crusher maintenance tools India – liming Mineral Processing The Whiting Group :: Sand, gravel, and mining industry equipment. rockcrusher The Whiting Group are recognized as an industry leader in the manufacture and

[خذ المزيد]

Construction, Working and Maintenance of ... - Practical

2018year12month26day Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

[خذ المزيد]

Crushers - All crusher types for your reduction needs - Metso

A large primary crusher is, naturally, more expensive than a smaller one. Therefore, the investment cost calculations for primary crushers are compared together against the total costs of primary stages, including quarry face clearing, blasting, and drilling costs. In many cases, dump trucks transport the rock to a stationary primary crusher.

[خذ المزيد]

Selecting the right crusher for your operations

2020year3month19day For example, a crusher’s discharge chute is under a lot of stress for the majority of the machine’s running time and, as a result, requires regular maintenance. To eliminate these extra costs, operators

[خذ المزيد]

Stone Crushers: A Technical Review on Significant Part of

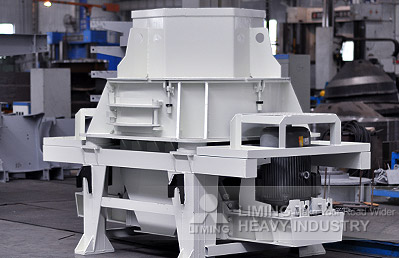

2022year5month14day 2 Concept of Stone Crusher. Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing.

[خذ المزيد]

sbm/sbm list of crusher maintenance tools.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

[خذ المزيد]

Attachments Tools - Products - Creighton Rock Drill Ltd.

Creighton Rock Drill Ltd. offers a large range of attachments by industry-leading suppliers. We sell world-class hydraulic and mechanical attachments from MBI, OilQuick, Astec (BTI), Epiroc Attachments Tools, Paladin Attachments, Simex Attachments and more. Whether it’s Silent Demolition or Material-handling Attachments, Site Maintenance or ...

[خذ المزيد]

Construction, Working and Maintenance of ... - Practical

2018year12month26day Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

[خذ المزيد]

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

2019year2month25day There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a

[خذ المزيد]

how much does a rock crusher cost - LinkedIn

2023year3month24day A rock crusher is an essential tool for mining and construction projects, but the cost of purchasing and maintaining one can be a significant investment. ... Additionally, the cost of maintenance ...

[خذ المزيد]

Top safety tips for working around crushing and screening equipment

2020year6month12day The biggest safety hazard in any quarry or recycling site is complacency; when employees have become too comfortable with their tasks and the equipment around them, according to Metso technical training instructor John Starck. Speaking during a recent webinar hosted by the company, Starck pointed out that of 14 fatalities that occurred in

[خذ المزيد]- مطحنة ريمون بالاهتزاز

- كسارة الدولوميت المتنقلة المصنعة نيجيريا

- بيع كسارة الخرسانة المحمولة

- أسعار الحصى سحقت الفلبين

- إسبانيا مصنع لتجهيز الخرسانة

- من جهة ثانية الفك سعر كسارة اليمن

- رمح عمودي تأثير كسارة العرض

- مطحنة تعمل بالطاقة المائية للبيع

- الكرة مطحنة التثبيت اليدوي

- كسارة الحجر vindhawashini haldwani رقم الجوال

- تستخدم كسارة الخرسانة المسار

- تستخدم المطاط الحزام الناقل بيع

- الشركة المصنعة لآلات كسارة في فادودارا

- تفسير حلم خلخله الاسنان لابن سيرين

- كسارة صخور للايجار في جنوب كاليفورنيا

- آلة طاحونة الكاكاو

- تستخدم كسارة التلفيف

- كسارة التعدين معدات كسارة التعدين

- الحجر الكامل المحمول معدات سحق 30tph

- شركة أسمنت في بروتيا غلين

- النسر سم مكعب تأثير محطم المحمولة

- آلة طحن hsm مطحنة الكرة الرطب لمصنع السيراميك

- وبعد عملية الحفر دعم نهاية حزام ناقل الحزام النقل

- مصنعي آلات تكسير الرمال

- تستخدم الرأسي أثر رمح محطم كندا

- رطل المحمولة كسارة الصخور

- تجهيز آلة من الحديد بدرجة منخفضة

- مطحنة الكرة سحق الكوارتز

- النباتات إثراء في ولاية كارناتاكا

- مخروط كسارات للبيع الولايات المتحدة الأمريكية

© Copyright - PETER&X محطم