used hammer mill disc rotor

Used Hammer Mills for sale. Fitzpatrick equipment more

Search for used hammer mills. Find Fitzpatrick, Jacobsen, Jeffrey, Bliss, Sprout Waldron, Alpine, Buffalo, and Weima for sale on Machinio.

[خذ المزيد]

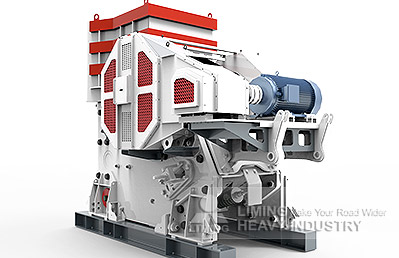

Unirotor Vario HUV - HAZEMAG

A vital component of the HAZEMAG Hammer Mills is the disc-type rotor, to which the moving hammers are mounted. The heavy-duty rotor is of a steel disc design, with free moving (360°) hammers mounted between the

[خذ المزيد]

Used Hammer Mills For Sale Perry Videx

2023year12month5day Hammer Mills. We've listed our inventory of used Hammer Mills, by size or manufacturer. Most of our Hammer Mills are available for immediate delivery and all are competitively priced. To see more

[خذ المزيد]

Used Hammer Mills For Sale Hammer Mills

Used Williams Crusher, Williams Pulverizer Co. hog mill with 2 rows of 2 swinging hammers and 2 rows of 1 swinging hammer, screen size 1/8 mesh, has top feed inlet of 19" x 12", side bottom discharge of 36" x 16", rotor

[خذ المزيد]

Hammer Mill HNM - HAZEMAG

HAZEMAG’s Hammer Mills HNM are used for fine crushing or mill drying of medium-hard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum,

[خذ المزيد]

Hammer mill HUM - HAZEMAG

The heavy-duty rotor employed in HAZEMAG’s Hammermills is of a steel disc design, with free swinging (360°) hammers mounted between the discs. The rotor is shaft mounted

[خذ المزيد]

Used Hammer Mills For Sale Machinery Equipment Co.

Mill, Hammer, 100 HP, Prater, Model G0S, Air Swept Pulverizer #S744813

[خذ المزيد]

Used Hammer Mills Buy Sell Used Mills - Aaron Equipment

Hammer mills have a high reduction ratio and high capacity and are relatively energy efficient. Hammer mills can be used for grinding many different types of materials. If you

[خذ المزيد]

hammer mill used machine for sale

Used hammer mill (impact crusher), model 97.58. Overall dimensions: Length 2960 mm Width 2090 mm Height 2065 mm Rotor diameter 0.8m Rotor width 0.6 m Number of

[خذ المزيد]

Hammer mill disc refurbishment process - Google Patents

A method and apparatus for a hammer mill's worn discs. The disc can be refurbished by removing a peripheral portion of the disc and placing a ring on the peripheral rim left on the disc. The ring preferably has a tapered, radially inwardly facing surface that abuts the peripheral rim of the disc to form annular gaps on both sides of the disc/ring junction.

[خذ المزيد]

CN212324796U - Rotor for hammer mill - Google Patents

2020year4month16day Rotor for hammer mill. Technical Field. The utility model relates to a straw rubbing crusher technical field specifically is a hammer mill is with rotor. Background. The straw crusher can crush corn stalks, straws, peanut skin, bean stalks, firewood and other combustible crop waste stalks. The method avoids the white burning of the crop straws ...

[خذ المزيد]

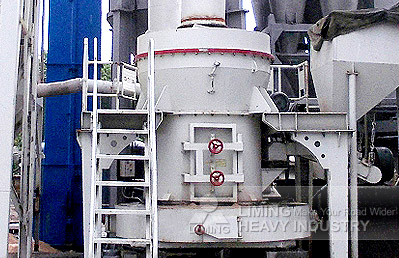

The difference between DISC MILL and Hammer MILL_Hebei

2018year11month26day The difference between DISC MILL and Hammer MILL. DISC MILL: crush materials via the interaction of pin inside,The helicoidal surfaces are produced mostly by form cutting with forming cutters of end mill type, side mill type or disc type.A disc mill, is a type of crusher that can be used to grind, cut, shear, shred, fiberize, pulverize, granulate,

[خذ المزيد]

Unirotor Vario HUV - HAZEMAG

A vital component of the HAZEMAG Hammer Mills is the disc-type rotor, to which the moving hammers are mounted. The heavy-duty rotor is of a steel disc design, with free moving (360°) hammers mounted between the discs. It is shaft mounted and fitted with self-aligning roller bearings. The rotor can also be operated in both directions ...

[خذ المزيد]

Energy consumption of two-stage fine grinding of Douglas

2018year3month12day The Rittinger constant of 104.5 for the rotor impact mill grinding is larger than 58.6 for the hammer mill grinding (Fig. 5), indicating that the hammer mill used less energy than the rotor impact mill for similar size reduction. However, it should be noted that they were not operated in the similar grinding regime; the rotor impact mill had a ...

[خذ المزيد]

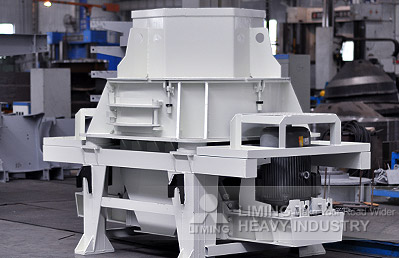

What is Hammer Mill? Working Principle

2 天之前 A set of swing hammers are attached to the high speed rotor disk. Swinging action of the hammers is beneficial in avoiding the build-up of the material between the hammer and the screen. Hammer mill may contain many rotor disks of diameter 150 to 450 min to which swing hammers of 4 to 8 in number are attached.

[خذ المزيد]

Hammer Mill - CAMCO Machinery Equipment LTD.

2021year4month22day The screenless hammer mill used air flow to separate small particles from larger ones. It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammer mills. The design structure of the hammer mill is always determined by the end use. Types of Hammer Mill Crushes can include “up ...

[خذ المزيد]

Used Hammer Mills Buy Sell Used Mills - Aaron Equipment

Hammer mills have a high reduction ratio and high capacity and are relatively energy efficient. Hammer mills can be used for grinding many different types of materials. If you are looking to sell your used hammer mill submit a request

[خذ المزيد]

The wear mechanism of mill beaters for coal grinding made

2022year12month1day Due to the blade-like structure of the rotor, the mill simultaneously acts as a centrifugal fan. Rotating the rotor causes a significant pressure difference between the inlet and the separator, thus causing an intensive circulation of hot air or exhaust gases along the way of the discharge path - rotor - chamber - separator - discharge [18 ...

[خذ المزيد]

Hammer Mill – Principle, Construction, Working, and

2022year8month29day This increased clearance helps to overcome excessive build occurring in the mill. Hammers are pinned to a rotor disk, and this disk is mounted on a single horizontal shaft. Several such rotor disks carrying 4 to 8 hammers are mounted on the central shaft in a conventional hammer mill. The diameter of the rotor disk ranges from 150mm to 250mm.

[خذ المزيد]

Hammer mill having capped disc rotor - Google Patents

The hammer mill for treating scrap metal including a rotary hammer means for delivering impact blows to scrap metal is shown. Discharge grates are provided for disposing of the scrap metal through discharge outlets for the hammer mill. The rotor is a disc type with rotating hammers located on pins extending through the discs. A plurality of caps are

[خذ المزيد]

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

The project deals with the Manufacturing with Design and Analysis of Hammer Mill Machine and Rotor Assembly of Machine of Capacity of 200 Kg/hr. Which is due to providing the transmission power of 5 HP to the machine. ... and, as the name implies, there is an offset between the vertical axes of the discs. The top disc has a conical section on ...

[خذ المزيد]

Hammer Mill HNM - HAZEMAG

MILL DRYING. FORMER PRODUCT LINE. HAZEMAG’s Hammer Mills HNM are used for fine crushing or mill drying of medium-hard to soft materials such as: Anhydrite, quicklime, lignite, dolomite, electronic scrap, gypsum, glass, potash, limestone, diatomite, chalk, phosphates, salts and clay.

[خذ المزيد]

Hammer Mill Construction, and Wroking Principal

2022year11month19day Hammer mill construction. The hammer mill consists essentially of a high-speed rotor turning inside a cylindrical casing. The rotor is mounted on a shaft which is usually horizontal. The swing hammers are pinned to a rotor disk. The hammers may be straight bars of metal with plain or enlarged ends. In this mill, the particles are broken by

[خذ المزيد]

Used Hammer Mills For Sale Perry Videx

2023year12month5day 200 HP Williams Hammer Mill. Stock #20631-311. Used Williams hammer mill serial #17991 , 26" X 9" feed with metal pull rolls, 30" diameter rotor, 200 HP 480 volt main motor with drive 9 belt pully. Free swing hammers with 4" main shaft. last used on virgin... Location: On Site at Perry (Hainesport, NJ - USA) Get a Quote View Details

[خذ المزيد]

A STUDY INTO HAMMER MILL ROTOR AND HAMMER

2017year12month3day rotated such that each hammer can be used in two or four different positions. Also, the hammers can be fixed or freely swinging, [4]. Studying the design of hammer in paper [5] the authors used as a baseline a commercial grinder. They attached to the mill two different hammer designs to the mill. Also, scientists changed the number of

[خذ المزيد]

Impact of industrial hammer mill rotor speed on extraction efficiency ...

2018year3month1day In the present work, the impact of hammer mill rotor speed on extraction yield and overall quality of super-high-density Arbosana olive oils were assessed in an industrial facility. Our results show that increasing the rotor speed from 2400 rpm to 3600 rpm led to a rise in oil yield of 1.2%, while conserving quality parameters. Sensory

[خذ المزيد]

DE202010017214U1 - Hammer mill and rotor of a hammer mill

Hammer mill (1) with a grinding chamber (2) that can be closed when used as intended and a rotor (10) which is arranged in the grinding chamber (2) and has a rotor shaft (11), several rotor disks (12, 12 ', 18, 19), which the rotor (10) into several segments (15, 15 ', 15'), and comprises several racket pins (20, 20 ', 20' ') for receiving rackets (23) or racket

[خذ المزيد]

Used Hammer Mills Buy Sell Used Mills

Hammer mills are commonly used in oil and gas, agriculture, mining, paper, and other similar industries. Hammer mills have a high reduction ratio and high capacity and are relatively energy efficient. Hammer mills can be used for grinding many different types of materials. If you are looking to sell your used hammer mill submit a request online ...

[خذ المزيد]- خطط سحق المعادن الموردين مصر

- كسارة مخروطية مثبتة على الجنزير للبيع

- آلات التعدين ليبر على الأرض

- آلات الحجر الصين للمحجر

- كسارة صخرية ذات سعة كبيرة

- الصين محمل كسارة الفك

- الصيانة الكرة مطحنة في مصنع للاسمنت

- بلجيكا كسارات مخروط المصنعين

- أفضل نوع من الثقل في خط السكك الحديدية

- كيفية التعامل مع الذهب التركيز

- ترسبات الطين الكرة سري لانكا

- حجر ألمانيا مبيعات آلة المطرقة

- كيف هي تشغيل محطات كسارة

- آلة طحن مطحنة دولوميت ريمون للبيع

- مصنع كسارة الحجر الابتدائية والثانوية

- توزيع حجم كسارة الأسطوانة

- مدير كسارة الصدم العمودية مصر

- المعدات الثقيلة اجزائها فيديو

- خرد کردن سنگ معدن آهن

- الجزائر كسارة الصخور المحمولة

- معدات تقطيع الحبوب

- تعلم آلة الكرة مطحنة الرطب

- مطحنة حطب القطن و الذرة

- شیشه ماشین خرد کن یونان

- بارو دنبال سنگ شکن سنگ

- كسارة الصخور نمط عباءة

- مطاحن الكرة لسحق خام الذهب

- خطورة الفرز آلة تشغيل واستخدام

- كسارة خام خلع الملابس المعدنية

- كسارة في urope للبيع

© Copyright - PETER&X محطم